|

|

|

|

|

|

|

|

|

|

Glen

Experienced Roboteer

Joined: 16 Jun 2004

Posts: 9481

Location: Where you least expect

|

Things were very slow at work today, so the chance was taken to give decimator a more thorough post mortem.

Aside from the very busted blade itself the rest of the hub assembly is fine. The bearings, shaft, hub itself and pulley still fit together great. The axle even fits in the frame perfectly. Very happy with that as i was worried the holes for the axle might get mashed out into an oval.

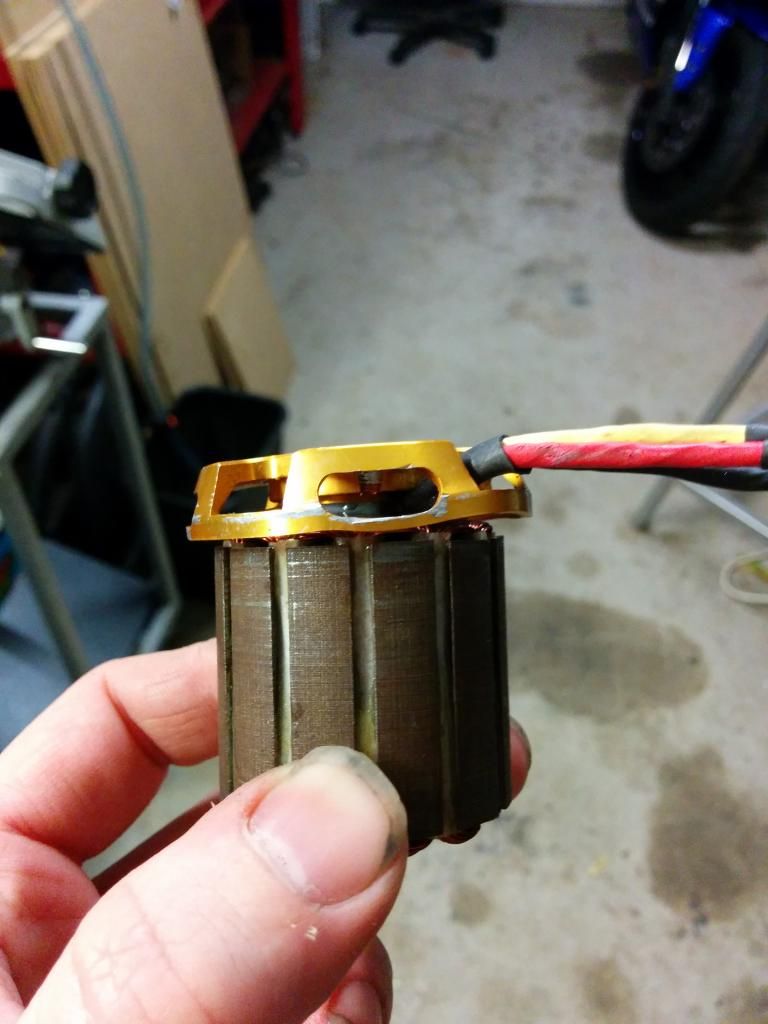

The weapon motor is a very sick puppy though. seems that they don't like being torn from their mountings  That stator tube is completely warped in every direction. Ouch! That stator tube is completely warped in every direction. Ouch!

The bearings, shaft and rotor itself are all fine though. So that's pleasing. Was very much expecting the threads to rip out but didn't have the time to sort it out pre event in the big rush. Would be a tricky job anyway because the mounting holes bisect the tube the stator sits on. It's a very odd design..

Also pulled the drives apart. Both gearboxes are fine (woohoo) but as i posted about before one motor dropped a magnet.

Not sure what to do next. The power and speed was great and the motors are cheap. But glueing them might be very tricky considering they aren't easy to pull apart.

Brushless is a definite option, but even using the slowest hobbyking sensored motors it will be too fast on the current 16:1 gearboxes. Lots of sensorless options about however. Could be worth making my own Hall effect board to sit inside a suitable outrunner... Otherwise will have to buy the higher ratio gearboxes and put the high kv sensored inrunners on those.

And for the weapon, the motor is an easy fix. Re-machining a much more substantial stator tube. Machining a single piece mount that just bolts direct to the robots chassis would be awesome, but don't think i could be buggered going to that much effort lol!

Still doing some FEA of my own on a new blade. But it's looking like a single tooth style bar waterjetted out of a prehardened block of 1 inch S7 tool steel will be cheap and tough. I'll get one cut out of mild steel for some testing. Sure it may have less energy, but given the rpm and weight its swinging, trading a bit of inertia for durability is a good deal imho.

Whether i fix the motor existing and belt drive is another thing to consider. REALLY keen to build a motor into the blade hub and dispense with the belt drive all together, but the stator is going to have to be a perfect size to make it all work. If anyone finds an old photocopier or something that has a stator with a bore larger than 20mm, hook me up!

Overall the damage total is -

- one busted drive motor (magnet fell out then blew up)

- bent blade

- the threaded brace in the middle ripped its threads out on both sides oddly enough.

- weapon motors stator tube is trashed in every way possible

- two busted fusion welds along the top from where the blades smacked into the front two panels.

Not too bad overall. Excited to get it improved for next time anyway.

_________________

www.demon50s.com - Minimoto parts

http://www.youtube.com/user/HyzerGlen - Videoooozzz

|

Wed Dec 31, 2014 1:10 am

Wed Dec 31, 2014 1:10 am |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RoboWars Australia Forum Index

-> Builders Reports

RoboWars Australia Forum Index

-> Builders Reports