|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Glen

Experienced Roboteer

Joined: 16 Jun 2004

Posts: 9481

Location: Where you least expect

|

Ahh geeze, Haven't posted since November. I swear I'm still alive. Just working working working, which is never a bad thing really cause i can finally get all the tools I've been dreaming of

Mostly spent the time since the nationals reorganising the workshop, getting some nice new tools and having the thing walled in. If anyone is a certified builder and wants to do it for me, please come and take my wads of money lol!

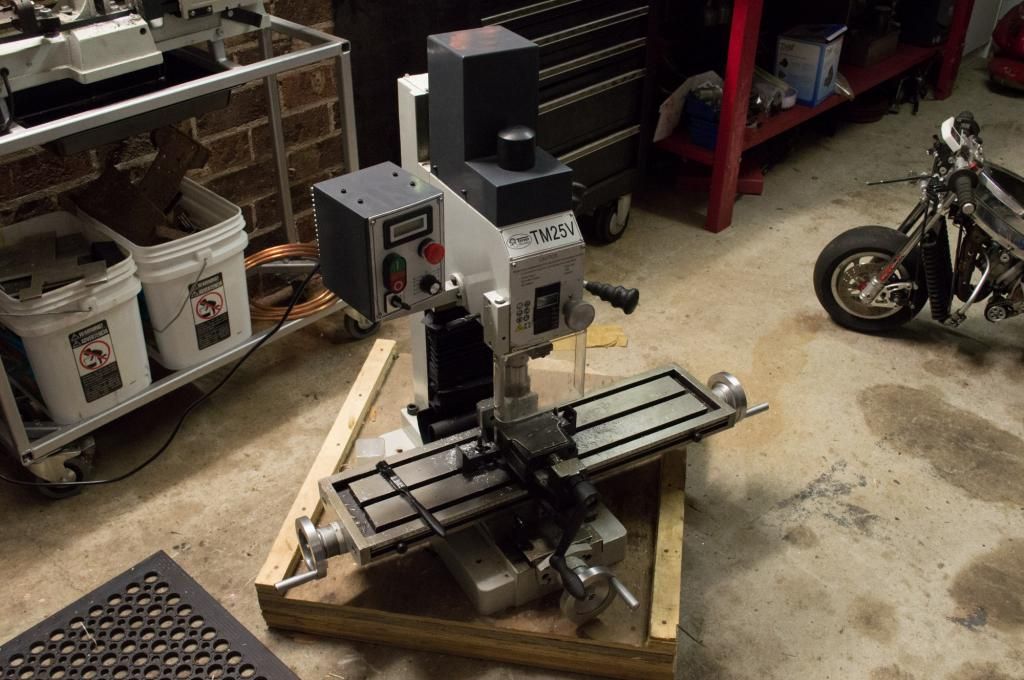

Anyways, might as well post up whats been happening. Had to fix a few of the typical horrors that lurk in chinese machines. The "bearings" (aka thrust washers) were all broken so they needed to be replaced in the Y axis, and the X axis didnt have any bearings on one side, so i had to lathe the cast iron end cap for them. What a horrible job.

Goes very nicely now however. Really impressed with it, managed to slot some 10mm steel in one pass without any hassle at all, and it's just sitting on its pallet still heh. Still gotta bring the stand home from work at some stage  My old X2 would have shaken to pieces attempting even half this cut seriously. My old X2 would have shaken to pieces attempting even half this cut seriously.

Bought all the tooling for it from CTC on ebay, for chinese items they really are nice quality and the runout of them is impressive, recommend them for sure. Just waiting on my tormach fly cutter to arrive and hav to shop for a rotary table then this puppy will be decked out nicely.

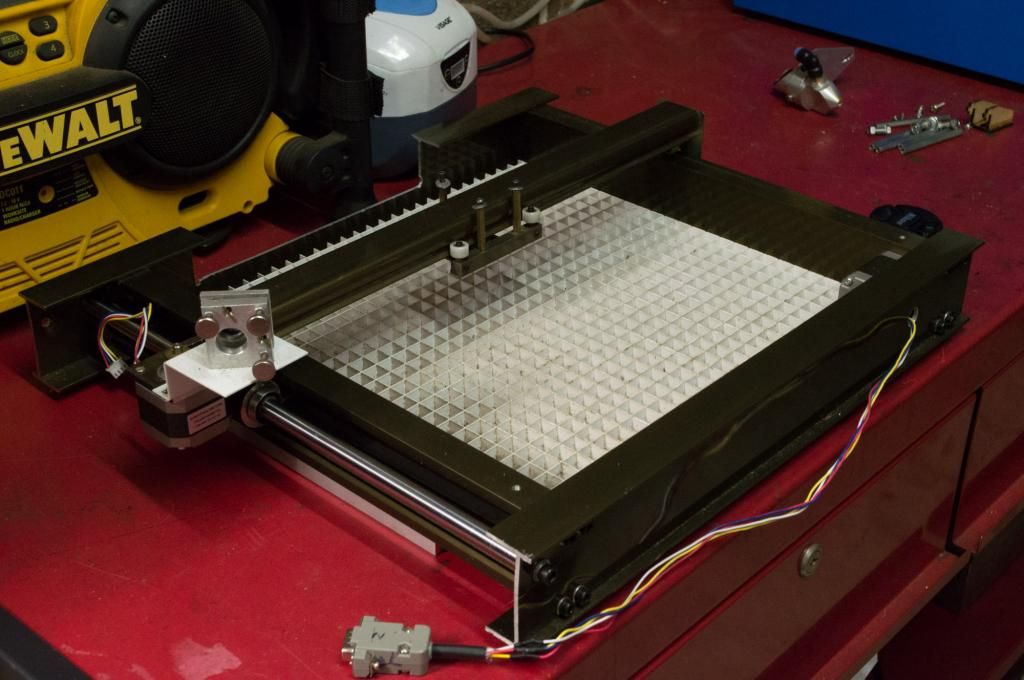

Laser cutter is getting towards legit completion. The laser power board somewhat crapped itself as my dodgy reattachement of the high voltage lines come apart and started zapping the case again. Really couldnt be bothered dealing with it anymore so i bought the nicer 60w power supply with PWM input.

Installed the new cutting bed as well as modding a few things to extend the cutting area. Plus i started on the adjustable height lens mount today for it. Then that should bring the mechanicals up to their final spec

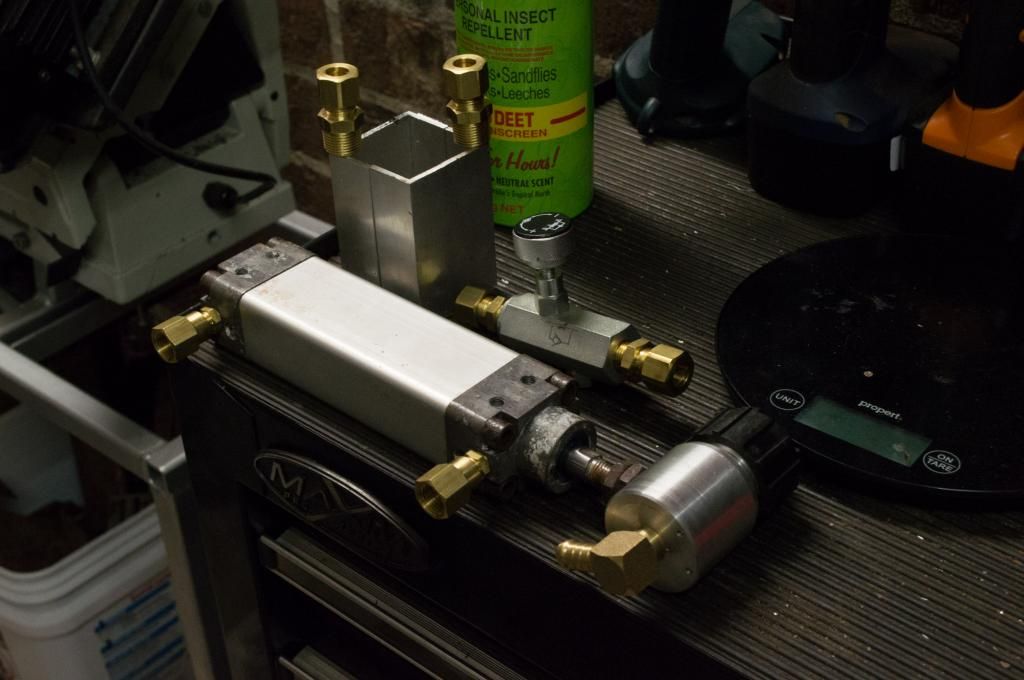

The heat exchanger for the laser tube also got some attention. Andrew found it for me in a scrapyard but the plastic coupler between the motor and pump was sheared. So i cooked up a new one out of magnesium, this was the first job on my mill too *sniffle*

The flat stub slots into the pumps input shaft -

Then the other side slips over the motors shaft to keep it centered. The bolt through the center engages in the matching slot in the motor.

When the tubing, flow sensor and silver anti bacterial coils show up i can plumb that up and call the job done  Might have to look at diverting some of the output flow though, she pumps pretty hard lol. Might have to look at diverting some of the output flow though, she pumps pretty hard lol.

And lastly, Finally got all the parts for my bandsaws hydraulic down feed from an completely useless ebay seller. The little spring and arm setup peeves me off so bad, so this makes it all quickly adjustable. The tank with the black cap is a temporary reservoir (its off my pocket bike heh) until i weld up the new one from the bits of U channel.

Need to weld up the rest of its mounts when things quieten down around work *yeah right*

As for the robots, definitely still have my flipper in the pipe work. Accumulating parts for it as i put together a vague design in my head. 4wd, two big drive motors and a 4 bar full pressure flipper based on hunchbacks system should give you some idea

_________________

www.demon50s.com - Minimoto parts

http://www.youtube.com/user/HyzerGlen - Videoooozzz

|

Sat Feb 15, 2014 11:44 pm

Sat Feb 15, 2014 11:44 pm |

|

|

|

|

|

|

|

|

|

RoboWars Australia Forum Index

-> Builders Reports

RoboWars Australia Forum Index

-> Builders Reports