|

|

|

|

|

|

|

|

|

|

Glen

Experienced Roboteer

Joined: 16 Jun 2004

Posts: 9481

Location: Where you least expect

|

PHEW where did the week go. So much crap raining down on me at once lol. Dat adult life. Forgot my new bikes nearly out of rego and frantically had to have it rebuilt in 3 days. All good now!

I forgot where i was up to previously, but this is what i've done.

Couldn't find the taps anywhere new for <$250 for all 3. The best ebay store in the world aka stores.ebay.com.au/Toolingstation?_trksid=p4340.l2563 tooling station provided all 3 in HSS for <$30. All of them are razor sharp too. Had a peek over the guys backyard while i picked them up, fuck me dead! he has SO MUCH STUFF IN THERE.

Next up was mcjing, needed a 15mm drill bit for the 3/8 bsp tap. $16 later and thats that. Have to say, everyone -needs- to go here for a shop if you own any machining tools. It's a heaven on earth. Here's 1x tiny bit of a table in there. Imagine this x 100. Place is huge and has everything. Great prices too compared to hafco.

Anyway back to the robot. Got the drive motors swapped over for some 12v kmart drills. Quite odd, one gearbox had all metal gears, the other had plastic and metal. But they both have 4 screws holding the motor plate to the gearbox and a D shaft and pinion making swapping pinions super easy. not bad for $20.

Both the bottles are mounted. Need to trim the top buffer mount down some but otherwise thats all good. Drilled and tapped all the holes in the ram. I accidentally tapped one of the 1/8 bsp holes to 1/4 and had to grab an adaptor, but thats good. means i can use a 1/4 bsp nitro valve for testing later

Flipper arms all tacked into place. Cut 500g out of it but still pretty heavy. Dont give a shit lol. How sick are plasma cutters though. LOVING IT. Just have to bolt some aluminium i beam into the arm and weld it all up.

Last of the pnuematic stuff showed up so no excuses not to finish it now. These on off paintball valves are so freaking body though lol. Drilled and tapped the buffer bottle which went smooth as silk even though i was shyting myself at the prospect of ruining it.

Last piece of the puzzle is making the manifold where all 4x hoses plumb into. Will be quite a complex piece requiring offset boring and all kinds of wierd crap, but im sure i can manage.

Biggest thing now is that hobbyking royally f*cked up my order for the batteries, they charged me $40 too much somehow then after taking the money out of my account have my order noted as unpaid, and i cant get in contact with them about it after 4 days. SO LIVID. So yes i think ill just buy from their resellers on ebay now. Been screwed around by them so much as of the last year.

So yeah getting there. Bits to do:

- make manifold

- Battery mount

- armour! no idea what to do yet.. 3mm polycarb and chopping board hello

- finish flipper arm

- finalise welding the rest of the chassis

Hoping all next week can be spent on the armour and working out the pneumatic flaws.. hopefully

_________________

www.demon50s.com - Minimoto parts

http://www.youtube.com/user/HyzerGlen - Videoooozzz

|

Wed Jul 24, 2013 10:01 pm

Wed Jul 24, 2013 10:01 pm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Glen

Experienced Roboteer

Joined: 16 Jun 2004

Posts: 9481

Location: Where you least expect

|

Lol i know, but the event is in 5 days, there is no time to do anything differently to how its done now, thats what i was implying. But yeah for sure i will probably do that afterwards. Do you just weld the tube to special BSP fittings or are you making your own?

WWELLITY WELL time flies. Bit annoyed bunnings stopped selling polycarb, so i didnt get the armour done. But i did work out the shape and mounting of it, so will have to go to plastix in the week and get some 6mm HPDE to do it out of.

The manifold was looking real heavy so i chopped a big ole sliver off it. Bandsaw horror 101

Got the flipper arm welded up. I ended up bolting two strips of aluminium inside it to stop it bending, meaning i can carve up the plate on the front to save weight ++. the strips add 300g but ill take 600 out of it, so all good. It also holds the 8mm bar the bungey + tether will attach to.

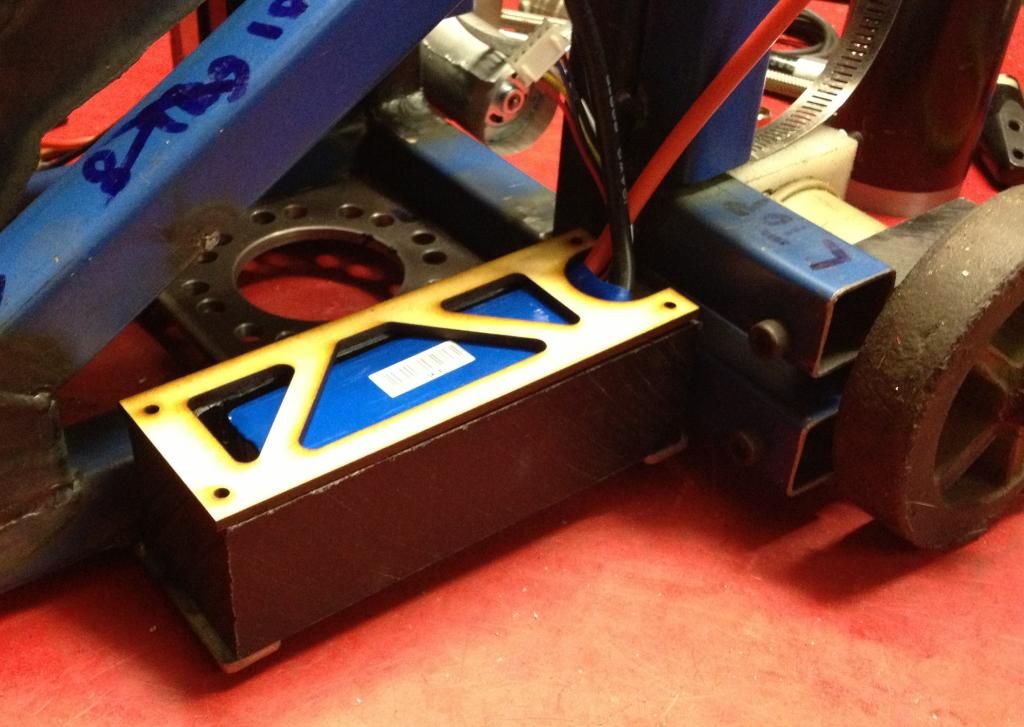

Cooked up the battery bay out of uhmw. Very light. Also lazored out a cover too lol. Will probably redo it out of hdpe or something. Or ill just leave it as wood just because :3

As for the pneumatics, cheers Phil for the metho tip, cleaned everything in metho in the ultrasonic and its all so shockingly clean lol. Just have to slap it all together and plug my compressor in (found a funky 1/4 bsp nitto fitting at a random toolstore) then i can test sometime.

Slowly chipping away.. I think the end is somewhere in sight.

_________________

www.demon50s.com - Minimoto parts

http://www.youtube.com/user/HyzerGlen - Videoooozzz

|

Sun Jul 28, 2013 9:14 pm

Sun Jul 28, 2013 9:14 pm |

|

|

RoboWars Australia Forum Index

-> Builders Reports

RoboWars Australia Forum Index

-> Builders Reports